test panels for surry seals|asphalt slurry seal testing : discounter TITLE: Outline Guide Design Procedure for Slurry Seal Download PDF . CODE: TB-112 TITLE: Method to Estimate Slurry Seal Spread Rates and to Measure Pavement Macrotexture Download PDF . CODE: TB-113 TITLE: Test Method for Determining Mix Time for Slurry Surfacing Systems Download PDF . CODE: TB-114 TITLE: Test Method for Wet Stripping of Cured . Login | Portal do cliente - Senior Sistemas. Olá, seja bem vindo! Faça o login para acessar o portal do cliente. Esqueceu a senha? Acessar como Consultor. Seu canal de relacionamento digital com a Senior. Aqui você .

{plog:ftitle_list}

Compare os voos das principais companhias aéreas e agências de viagens e encontre .

This test kit comes with rectangular beam-type molds, rubber wheels, and software to collect and store test data on the user’s PC. Features: Includes components needed for micro surfacing and slurry seal testing. Tests in .Slurry systems are pavement preservation surface treatments that encompass micro surfacing, slurry seal, and polymer modified slurry seal. Each treatment type is designed to extend the .Test Methods for Emulsified Asphalt Slurry Seal 6.1 Consistency Test: 6.1.1 This test method is used to determine the proper consistency (mix design) for a slurry seal mixture.Espesor del Sistema Slurry El espesor de una capa de slurry seal es de 6 milímetros, cabe mencionar que dicho dato es un valor promedio, ya que el espesor del sello slurry va a depender del tipo de slurry que estemos .

TITLE: Outline Guide Design Procedure for Slurry Seal Download PDF . CODE: TB-112 TITLE: Method to Estimate Slurry Seal Spread Rates and to Measure Pavement Macrotexture Download PDF . CODE: TB-113 TITLE: Test Method for Determining Mix Time for Slurry Surfacing Systems Download PDF . CODE: TB-114 TITLE: Test Method for Wet Stripping of Cured .

If you're looking for a way to breathe new life into your asphalt surfaces, you may have come across a slurry seal as an option. This product has been used for years as a way to protect and extend the life of asphalt .improve the performance of slurry seal and micro-surfacing systems through the development of a rational mix design . – 4 Advisory Panel Surveys † Current Mix Designs † Current Use of Technologies . Slurry Seal Design Automated Mixing Test (AMT) ISSA TB 100 – Test Method for Wet Track Abrasion of Slurry Surfaces

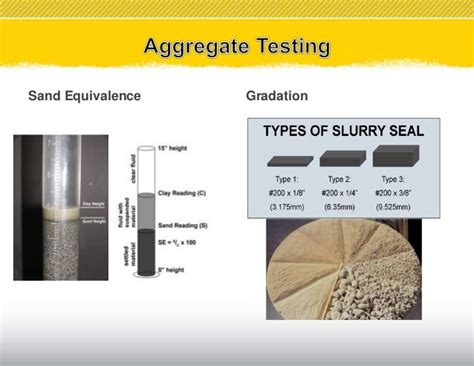

Slurry mixtures are made of fine aggregate, emulsified asphalt, and water mixed in specific proportions within a specialized, truck-mounted or self-propelled machine. . Chip Seals are made by spraying a layer of emulsified asphalt or rubberized asphalt onto the pavement and covering it with a layer of clean, crushed, cubical aggregate using a .15. 7-Year Type 2 Slurry . Longitudinal, Transverse 3.7 1.1 16. 10-Year Hot Mix .Longitudinal 4.8 1.5 17. 10-Year Hot Mix . Longitudinal,Transverse 3.5 1.1 3. Spread Rate Calculation and Report 3.1 Assuming a moderate squeegee contact pressure, a slurry consistency of 2.5 to 3 cm and a slurry depth of 5 to 6 inches8.1.2 Purpose of a Slurry Seal A slurry seal is a thin surface treatment that is laid in a thickness equal to the largest stone in the grading of its component aggregate. It may include either a conventional or polymer modified emulsion, and the slurry seal may be slow or quick setting. The emulsion is usually cationic in nature, but may be . 1. Slurry Surfacing Aggregate 10 2. Aggregate Tests for Slurry Surfacing 21 3. Slurry Seal Mix Design Proportion Limits 25 4. Residual Asphalt per ISSA 25 5. Slurry Seal Mix Design Tests 25 6. Application Rates for Slurry Seals 26 7. Microsurfacing Mix Design Requirements 28 8. Application Rates for Microsurfacing 28 9. Example Sampling Control .

slurry seal design standards

En este #inarTDM impartiremos los conocimientos fundamentales sobre la selección de los materiales, criterios de diseño y aplicación en obra del Slurry Seal.The Recommended Performance Guidelines for Emulsified Asphalt Slurry Seal and Micro Surfacing, ISSA A105 and A143, provide specific target values for cohesion results at 30 and 60 minutes. 2. Referenced Documents . 3.1 This test quantifies the time required before a slurry surfacing system may be subjected to straight rolling traffic. 4.SLURRY SEAL SURFACING. (REV 9-15-14) SECTION 335 SLURRY SEAL SURFACING 335-1 Description. . The cement mixing test shall be waived for this product. The polymer material shall be co-milled into the asphalt or added to the emulsifier solution prior to the emulsification process. The amount of polymer modifier shall not be less than 3.0% polymer

In part one of our two-part series on the best practices of micro surfacing and slurry seal applications, we share all of the basics and best preparation practices. In part two, forthcoming in the Spring 2020 issue of Preservation Pro, will dig into the best practices on the job site. . “Test strips assure adequate workmanship, aesthetics .CRACK SEAL + SLURRY SEAL: When cracks in the existing surface exceed 1/4 inch (0.6 CM) in width, crack sealing them in advance of slurry seal will help keep water from intruding deeper into the pavement structure after the cracks reflect through the new wearing surface. Abstract. With the increasing attention to preventive maintenance and rehabilitation of asphalt pavement, asphalt emulsions have gained popularity. Synchronous chip seal (SCS) and slurry seal (SS) are widely used in pavement preservation due to their low cost and efficiency but are not prevalent in new pavement construction, especially for airport pavement. .When design depth is reached, the slurry is displaced with concrete pumped through a tremie pipe to the bottom of the panel, and steel reinforcement is inserted. The finished walls can function as groundwater cutoff and soil .

Slurry seals are better suited for larger, high-traffic areas where durability is critical, while seal coatings are better suited for smaller areas where cost and ease of application are more important considerations. Ultimately, the choice .

Overlays/ slurry seal. Limitations. Design . The mixing/coating test Slurry > 5 minutes Microsurfacing 90 – 120 s 0 0,5 1 1,5 2 2,5 0 20 40 60 80 100 120 140 Mixing time (s) Ad d i t i v e (p p h) 20°C 10°C. Consistency test. Recommended design approach

5.4.7 Wet Track Abrasion Test—This test method covers measurement of the wearing qualities of slurry seal under wet abrasion conditions. NOTE 4—As a guide, slurry seal shall not show a loss of more than 75 g ⁄ft2. 6. Test Methods for Emulsified Asphalt Slurry Seal 6.1 Consistency Test: 6.1.1 This test method is used to determine the proper The results of the sand patch test on WTAT samples showed that slurry seals made with RAP should be lightly rolled after lay-down to improve their friction life. Cost analysis indicates that the use of RAP as an aggregate in slurry seal decreased costs by up to 14%. RAP slurry seal showed better overall performance with lower cost than the .

ut hardness tester

A longer look at an updated job to highlight all aspects of slurry seal being applied to preserve pavement in Cecil County, Maryland. For pavements still in.Engineered Seal Products provides shaft seal dust and slurry testing, which is a bolt-on option to their hot oil seal test machines. Contact us today for a quote! Color. 1.866.412.4880. Companies . Industrial Seal; . This is a bolt-on option to our hot oil seal test machines. It allows you to introduce media to the excluding features of the seal.Slurry Seals cost 1/10th of the typical pavement overlay and is considered a regular maintenance method. Slurry seals are meant to preserve roadways in good condition for longer periods of time. They are not meant to be placed on significantly cracked or damaged roadways.

various hardness testing methods

CDPH Slurry Seal Product Related Media & Downloads. Warman WBH Range Conversions. Mining & Mineral Ore Double Slurry Seal. Mining company saves million AUD with AESSEAL system. AESSEAL system eases cost pressures for African company. Mechanical Seal upgrade improve reliability and saves more than ZAR 580,000. If slurry walls are intended to act as cut-off walls without any loadbearing function, a mixture of water, bentonite, cement and maybefiller can be used.This slurry remains in the excavated panel and hydrates. It alsoremains as a plastic seal, so that the wall can follow smalldisplacements in the soil without cracking.TB No. 114 Test Method for Wet Stripping of Cured Slurry Surfacing Mixtures . TB No. 115 Determination of Slurry System Compatibility . 2.2 ASTM Standards: C 136 Sieve Analysis of Fine and Coarse Aggregates . D 6933 Standard Test Method for Oversized Particles in Emulsified Asphalts (Sieve Test)

1.1 This test method measures the mixing time of a specific combination of materials for a slurry surfacing system. The Recommended Performance Guidelines for Emulsified Asphalt Slurry Seal and Micro Surfacing, ISSA A105 and A143, provide specific target values for mix time results at 25°C (77°F). 2. Referenced DocumentsChip Seal A165 NOTICE . International Slurry Surfacing Association 800 Roosevelt Road Building C-312 Glen Ellyn, IL 60137 www.slurry.org . Failure to meet the specification for an individual test does not necessarily disqualify the system. If, for example, the system to be used on the project has a record of good .

slurry seal design practices

slurry seal design and testing

webEncontre a loja Zema mais perto de você. Conheça aqui os nossos serviços da sua região

test panels for surry seals|asphalt slurry seal testing